Bolted connections are among the most heavily stressed parts of a wind turbine. As safety-relevant components, bolted connections are exposed to continuously acting dynamic forces during the life of a wind turbine, which can cause cracks, damage and fractures in the bolts. For a safe and reliable operation of the wind turbine, the bolted connections must be monitored regularly.

Our bolt monitoring solutions provides information on the condition of the bolts at the connection of rotor blades, tower segments, foundations, and anchor rods. Users can remotely monitor the tightness of bolted connections, receive early warnings and alarms of bolt failures, and track progressive bolt loosening over time.

Based on non-intrusive sensors, extremely low-power technology, long-life and replaceable internal batteries, and reliable wireless data transmission, our solutions are designed for easy installation and continuous operation without maintenance for years in harsh environment.

We offer two different sensing technologies for monitoring bolt connections: bolt preload sensing and bolt loosening sensing.

Bolt Preload Sensing:

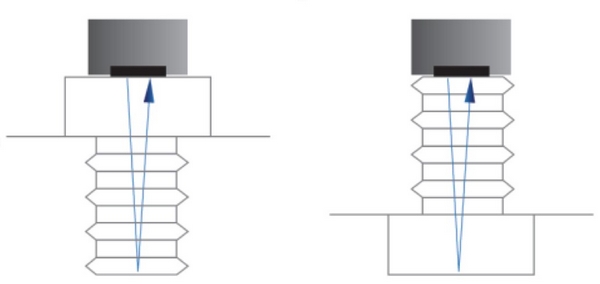

The function of a bolt is to apply a clamp force, known as preload and measured in Newtons, in a bolted connection. The correct preload ensures the connection’s safety and durability.

A wireless bolt preload sensor is mounted on the bolt head and periodically measures the bolt preload. Each sensor has a built-in ultrasonic transducer. At the time of measurement, an ultrasonic signal is passed through the fastener and reflected at the end. The sensor uses the time-of-flight of the ultrasonic signal and the temperature to calculate the preload, with an accuracy within 2% of the actual preload.

Bolt Loosening Sensing:

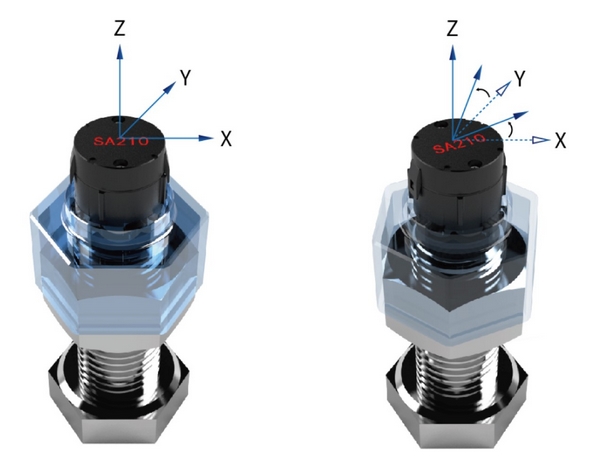

While bolt preload sensing technology provides direct and the most accurate measurement, bolt loosening technology offers a cost-effective alternative by measuring the rotation angle of a bolt or nut.

A wireless bolt loosening sensor is permanently clamped on the nut and periodically measures the rotation angle of the nut relative to the bolt, with an accuracy within ±0.5°.

Data collected from all sensors in a wind turbine are transmitted to a remote monitoring system via a single wireless gateway.

Key Advantages:

Non-intrusive: No impact on the structure or strength of the bolt.

Accurate: High accuracy of less than ±2% of the preload or ±0.5°.

Easy-to-install: Compact, lightweight, and mounted with epoxy or clamp.

Low-powered: Built-in battery with 10 years of life for normal usage.

Ruggedized: Waterproof, dustproof, shockproof, and corrosion-resistant.

Accessible: Remotely accessible anytime, anywhere.

Intelligent: Early detection of critical bolt damages; continuous monitoring 24/7.

Our solutions increase the safety and longevity of critical assets, reduce downtime by optimizing operation and maintenance activities, and help drive smarter, faster business decisions for wind power operators.