Wind Turbine Bolt Monitoring Deployment of Mountain Wind Farm

We have successfully deployed bolt monitoring system in a wind energy facility consisting of 17 3MW direct-drive wind turbine generators.

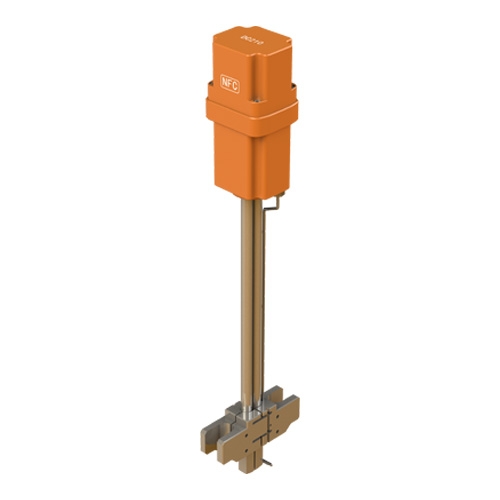

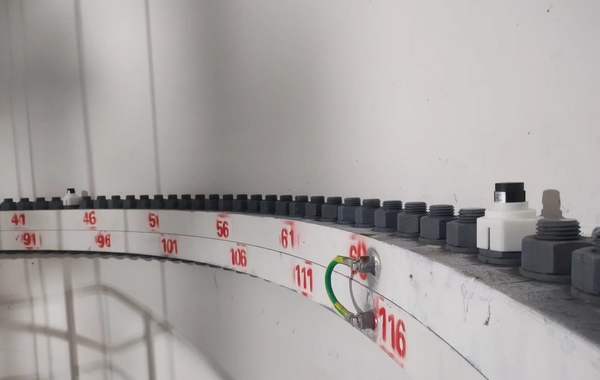

For each wind turbine, 24 wireless bolt loosening monitoring sensors (model SA210) , each monitoring the rotation angel of a bolted connection, are installed on bolt-nut joints of three tower flanges. All sensor data is transmitted to the bolt monitoring system via a single wireless gateway (model GU100P).

The installation of each wireless sensor is extremely easy. With no cable or wiring, each sensor can be directly clamped onto the nut with the right adaptors. Sensors are evenly distributed along the along the circumference of each flange. The complete installation and deployment for a single turbine is less than one hour.

Each sensor is designed for ultra-low power consumption and has a battery life of more than 10 years for normal usage.

User can remotely monitor the status of bolted connections through an intuitive graphic user interface, receive early warnings and alarms of bolt loosening, and track progressive bolt loosening over time.

Our remote bolt monitoring system increases the safety and longevity of wind turbines, reduce downtime by optimizing operation and maintenance activities, and help drive smarter, faster business decisions for wind power operators.