Cable Clamp Bolt Monitoring for World’s Longest Cable-stayed Bridge

During the long-term operation of the cable-stayed bridge, bolt joints are frequently subjected to loosening and damages due to vibrations, stress, and temperature variations. This may cause cable clamp slippage, structural linear change, function loss of the main cable dehumidification system at the slippage, or other damages.

Cable clamp bolts are located in high and hard-to-reach areas and manual inspections are time-consuming, labor intensive, and risky.

We have successfully deployed bolt monitoring system for world's longest cable-stayed bridge as part of bridge health monitoring system upgrade, enhancing the inspection and monitoring process by making it safer, inexpensive and less time-consuming.

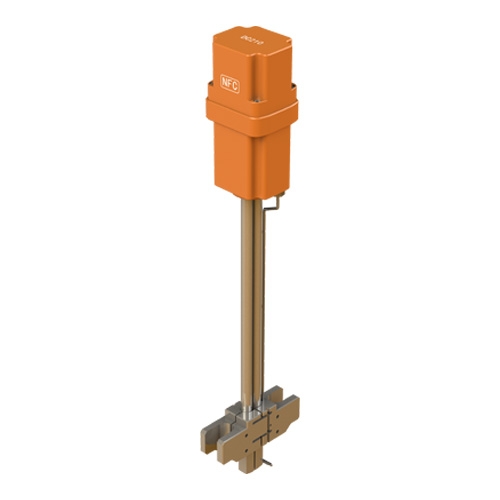

Wireless bolt preload sensors (model SAS100) are used to monitor the preload of selected fasteners. All sensor data is transmitted to the bolt monitoring system via the 4G connection on the wireless gateway (model GU100P).

The installation of each wireless sensor is extremely easy. With no cable or wiring, each SAS100 sensor can be mounted to the bolt end.

Each sensor is designed for ultra-low power consumption and has a battery life of more than 10 years for normal usage.

User can remotely monitor the status of bolted connections through an intuitive graphic user interface, receive early warnings and alarms of bolt failures, and track progressive bolt loosening over time.

Our remote bolt monitoring system increases the safety and longevity of bridge, reduce downtime by optimizing operation and maintenance activities, and help drive smarter, faster business decisions for bridge operators.