Bolt Monitoring Deployment of 500kV Power Transmission Towers

The power transmission tower is important structure equipment in the power system. The transmission towers are usually constructed with zinc coated angle steel and connected with bolts. The connected bolts may become loose under load, vibration, and temperature variation for a long time. As a further effect, the dynamic behaviors of the tower may change and lead to tower structure failure. Therefore, bolt health monitoring is very important, especially at the early stage of loosening.

Manual inspection is time-consuming, labor intensive, and sometimes risky. It may also require specialized equipment and expensive insurance covers for the workers and equipment.

Our bolt monitoring system was successfully deployed in transmission towers of a 220kV power line, enhancing the inspection and monitoring process by making it safer, inexpensive and less time-consuming.

For this project, wireless bolt loosening sensors (model SA210) are used to monitor rotation angel of the nut relative to the bolt.

The installation of each wireless sensor is extremely easy. With no cable or wiring, each sensor can be directly clamped onto the nut with the right adaptor.

Each sensor is designed for ultra-low power consumption and has a battery life of more than 10 years for normal usage.

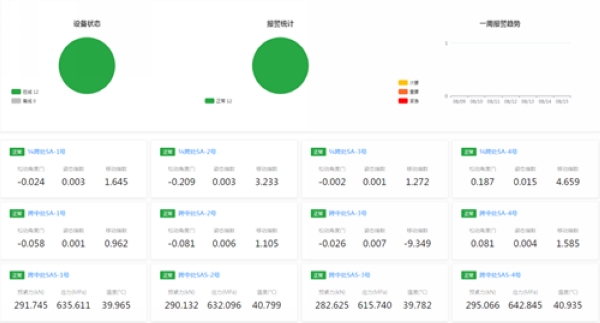

All sensor data is transmitted to the bolt monitoring system via the 4G connection on the wireless gateway (model GU100P). The gateway is powered by industrial solar panel.

User can remotely monitor the status of bolted connections through an intuitive graphic user interface, receive early warnings and alarms of bolt loosening, and track progressive bolt loosening over time.

Our remote bolt monitoring system increases the safety of the power transmission, reduce downtime by optimizing operation and maintenance activities, and help drive smarter, faster business decisions for energy operators.