Vibration Monitoring System Deployed in Steel Plant

It is normal for machines to vibrate, but a change in a machine’s vibration patterns can indicate potential problems. Measuring changes in vibration patterns helps teams identify imbalance, looseness, misalignment, or bearing wear in equipment, before failure occurs. Abnormal or excessive vibration creates premature wear in components and can shorten asset life.

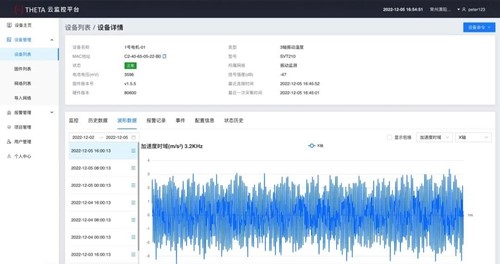

Our wireless vibration monitoring solutions make it easy and cost effective to monitor a variety of vibration characteristics and set warning and alarm thresholds, as well as collect vibration data over time for trending and analysis.

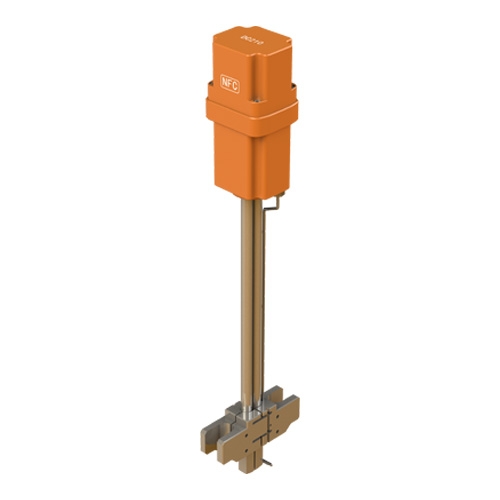

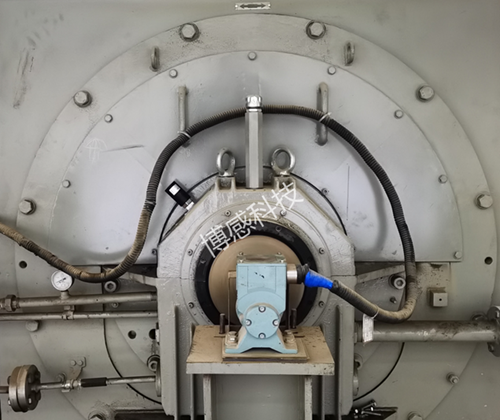

Our wireless vibration sensors (model ST210) were deployed in a steel plant to monitor changes in the amplitude, frequency, and intensity of vibration of their major equipment. All sensor data is transmitted to the corrosion monitoring system via the 4G connection on the wireless gateway (model GU100P).

Each sensor is designed for ultra-low power consumption and has a battery life of more than 2-5 years for normal usage.

Businesses benefit from several key advantages:

· Eliminate costly downtime due to motor failures

· Schedule maintenance more efficiently

· Easily monitor remote and hard to reach assets using wireless vibration monitoring

· Send data to the cloud and access remotely