Bolt Monitoring System Deployed in Major Subway

Rail joints are an important yet weak component in railway tracks because of the large impact and wheel-rail contact forces. Every train passage contributes to the deterioration of rail joints, causing visible (e.g., battered rails) and invisible (e.g., loose bolts) damages. The invisible damage cannot be detected by the commonly performed visual inspection, which is labor intensive, unreliable, intrusive, and unsafe. The impact of the train vibration during the daily running will loosen or break the fasteners, which will further lead to the loss or damage of the fasteners, which will seriously affect the train running safety, or even cause a train derailment accident. Therefore, the condition detection of the railway fastening system, looseness or absence, is an important task in railway maintenance.

Our bolt monitoring system was successfully deployed in a major subway system, enhancing the inspection and monitoring process by making it safer, inexpensive and less time-consuming.

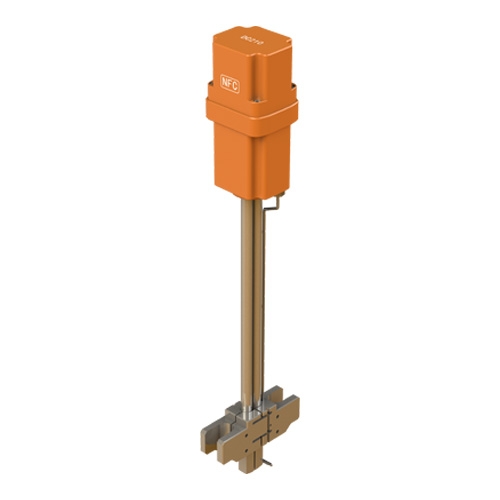

For this project, hundreds of wireless bolt loosening sensors (model SA210) are installed on critical bolts of subway turnouts. All sensor data is transmitted to the bolt monitoring system via the wireless gateway (model GU100P).

Each sensor is designed for ultra-low power consumption and has a battery life of more than 10 years for normal usage.

Our remote bolt monitoring system increases the safety and longevity of subway, reduce downtime by optimizing operation and maintenance activities, and help drive smarter, faster business decisions for subway operators.